By H.L. Hucbald ap Urp

Apprentice to Master Cathal Sean O'Conlin,

In service to the people of An Tir

April 14, 2007 (A.S. 41)

A Leonardo da Vinci Leaf Spring Catapult

|

By H.L. Hucbald ap Urp Apprentice to Master Cathal Sean O'Conlin, |

|

The Leonardo da Vinci Catapult

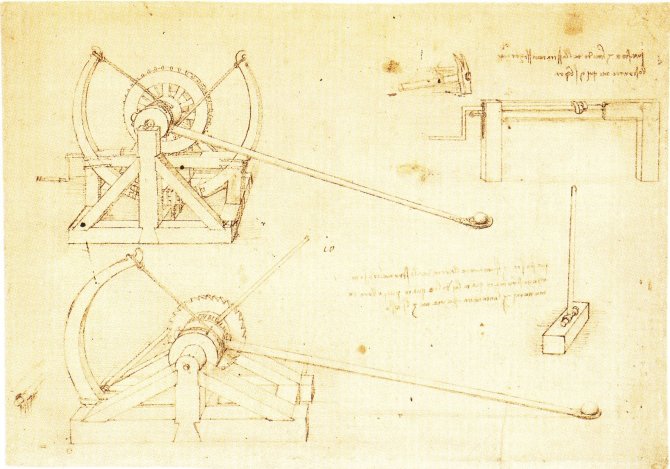

The basic design of the catapult had been used for hundreds of years before Leonardo da Vinci turned his mind to trying to improve it. Among the sketches that Leonardo drew are some designs for using leaf springs with catapults. While the modern leaf spring is not depicted certainly one could be used. The issues of creating spring steel in large enough sections would have been difficult and have made this new catapult prohibitive in cost alone. The designs show that a wooden leaf spring was planned. This leaf spring would have been much like the great bow on a catapult but with a greater arc.

Codex Atlanticus, ff 140ar - Leonardo's Machines, Da Vinci's Inventions Revealed

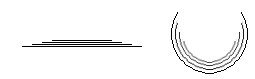

The leaf spring is much like a bow. The centre is thicker and harder to bend. Towards the ends the leaf spring becomes thinner and easier to bend. This allows for each section to lend its rigidness to the bending action. Layers of wood would have been built up, each shorter than the previous.

States of a leaf spring - Hucbald ap Urp

The ingeniousness of this design comes from not the traditional method of using a bow to pull the catapult arm up towards its stopping point but to rapidly spin a drum on an axel that the throwing arm was attached to. This gives a great acceleration to the throwing arm. Each end of the leaf spring has its own bow string. Each bow string then attaches to the same side of the drum. This has the effect of a ripcord spinning motion similar to a pull start on a lawnmower. Each end of the leaf spring lends its springiness to the entire leaf spring.

At the end of the throwing arm the throwing cup resembles a lightly dished oar. This small dish would have allowed the projectile to roll easily from the throw. To control the release point the paddle most likely would have had a shim or small piece of wood placed behind the projectile. This would have simply held the projectile in the dish longer until the centrifugal force would have allowed the projectile to roll over the extra piece and then be released. This would have had the effect of flattening the arc while allowing the throwing arm to accelerate to a faster release speed.

Throwing Results

The basic range was about 28 - 33 feet. The first time this was measured the catapult was resting about two feet above the ground and rang a spittoon sitting on the floor. The distance was paced out as approximately 33 feet.

Further testing was taken outside for fear of putting holes in the wall. Using a 100 foot tape measure, distances were recorded from ground level to ground level on average between 28 and 33 feet.

After trying small rocks it was found that these had a tendency to stay longer in the throwing cup. This was attributed to the surface irregularities of the rock. As the first indoor test used a small wooden cube bead, we switched to this to record the 28-33 foot range.

The bottom of the throwing arm wheel is shown in Leonardo's drawings as having a hand crank to cock the throwing arm. This was estimated to be 3 feet off the ground for ease of cranking. This means that this model has a scale of 1/36 or 1 inch equals 3 feet. Basing the distances on this scale the catapult was throwing just under a quarter mile. Ranges may also be expressed as 19-23% of a mile or 1008 - 1188 feet. (A quarter mile would be 37 feet)

The catapult at rest.

The catapult cocked.

Design Notes.

The wood used is base wood. This is available at just about any craft store or hobby store. Even some hardware stores will carry it. There was no plan for this and all measures were compared for best fit. In fact, the only measures made were for the leaf spring and the height off the ground for the throwing wheel to determine scale.

The dowels for pegging joints, the axel and the throwing arm are common doweling found in the same places as base wood. Usually this is hemlock. The drum was found in a craft store and is a wooden thread spool. I chose one with a tapered centre to cause the winding of the bow strings to follow to each side. The wheel is a hobby wheel also made of indeterminate wood.

Close up 1.

The entire axel with drum and throwing wheel are made one piece by driving small dowels through the sides of the wheel into the drum and also through the drum and axel. The dowels that went through the drum and axel also serve as posts for the bow strings to loop onto. For additional strength, all joining dowelling was glued with wood glue. The dowels were not cut flush to resemble more of a hand driven pegging.

What may not be noticeable is that the uprights that hold up the axel are each made of two pieces. These are twice pegged in the lower half to help bind the uprights together. Also, out of sight is a peg through the bottom of each post to add strength to the upright joining to the frame.

Close up 2.

The leaf spring is made of pallet banding. This can be found at any lumber yard and to them is garbage. It's used to hold together pallets of dimensional lumber. I chose this form of leaf spring rather than the wooden one that is implied in Leonardo's drawing for two reasons. One, I was running shy of time for the dead line I had set. And two, I've been planning another project using specifically this style of leaf spring and thought this would be an excellent trial. The leaves were drilled in the centre and anchored to the base using a carriage bolt.

The throwing cup is a medium sized bell that can also be found in a craft store. Three sides of the bell were cut off and the fourth side bent back. The fourth side was then inserted into the end of the throwing arm. This in turn was wound with jute twine.

The bow strings are made out of jute twine. This was used to have strength and appearance of rope. The knot at either end is known as a bowstring knot.

Alterations I would like to make.

The throwing cup should be replaced with a throwing spoon. The original design appears to call for a wooden spoon with a shallower dish. This dish would have been enough to hold the projectile and being made of wood would have allowed for 'release arc shims' to be placed behind the projectile. This would have caused the projectile to stay in the spoon longer, until the centrifugal force caused it to roll out. For this change I plan to use the spoon off of a fishing lure. This will allow bending to replace shimming.

The leaf spring should be replaced with more of a period style bow. It's unlikely that a metal leaf spring of this magnitude could or would be considered. The expense alone would have been prohibitive. Without creating a layered bow a tapered one should work just fine and can be steamed into shape using either a steam box or possibly over a kettle.

The nature of the design is for the leaf spring to pull upwards and lift the frame off the ground. The original design would have had the frame anchored to the ground to prevent this.

Possible SCA uses.

Leonardo also created the design of a single leaf spring catapult. It may be possible to use half a war bow and the spool from electrical wire to launch fuzzy yellow death (tennis balls) at a fair rate of fire. The half bow would mount at the front at an angle and a full length bowstring could be used.

The pallet banding leaf spring might be an alternative, if built up to greater layers and strength, for target crossbows.

Sources.

Domenico Laurenza. Leonardo's Machines, Da Vinci's Inventions Revealed.

Ed. Mario Taddei and Edoardo Zanon. David & Charles 2006. 102-107.

"Single Loop Knots" 1997.08.08. Roper's Knot Pages.April, 2007

< http://www.realknots.com/knots/sloops.htm >

Venki. Single loops / The Bowstring Knot.

< http://venki.somee.com/Single_loops.asp?ID=4 >